What is Ultra Compact Surfacing?

The latest in countertops: Ultra compact surfacing. A brand-new type of countertop surface, ultra compact surfacing is created with a unique manufacturing process that yields unique and beautiful results. Here’s everything you need to know about this option for your countertop makeover.

Ultra compact surfacing is a sophisticated combination of the same raw materials that go into glass, porcelain and quartz countertops. But it’s manufactured in a unique way, called Sinterized Particle Technology.

This high-tech process mimics the metamorphic change that natural stone undergoes when subjected to high temperatures and pressure over thousands of years—but at an accelerated pace. By compressing raw materials at upwards of 5,900 psi and using ovens that reach 2191oF, the result is exceptional strength and other superior technical characteristics.

Here’s why this countertop surface might be a great option for your kitchen, bath or even outdoor countertop needs.

Why Ultra Compact Surfacing?

Ultra compact surfacing provides unique UV resistance, exceptional strength, high resistance to impact, scratches and abrasion, thermal shock resistance and very low water absorption.

Versatile Use: Indoor or Outdoor

Ultra compact surfacing can be installed as indoor or outdoor countertops. No matter how hot or cold it is outside, this surface will endure. And the high UV resistance means that the color will not fade despite exposure to the sun.

Ideal for Busy Households

These countertops are extremely durable. With exceptional strength and a high resistance to impact, scratches and abrasion, they will hold up no matter how active your household.

Other materials are also durable in comparison, but the key difference of ultra compact surfacing is that it also doesn’t stain nor require any sealing. The material is non-porous with virtually zero water absorption, so any spill will be easily removed. This also makes the surface extremely hygienic for food prep, because bacterial won’t absorb into it.

Unique Characteristic: Thermal Shock Resistance

This type of surface is uniquely resistant to thermal shock, which refers to a rapid change in temperature. Because the material is manufactured through a high pressure, high heat process, it can tolerate extreme temperatures.

Granite is also highly heat resistant. Just like Granite, you don’t have to worry as much about putting a hot plate down on the ultra compact surface—but it’s still wise to do so to make the most of your investment!

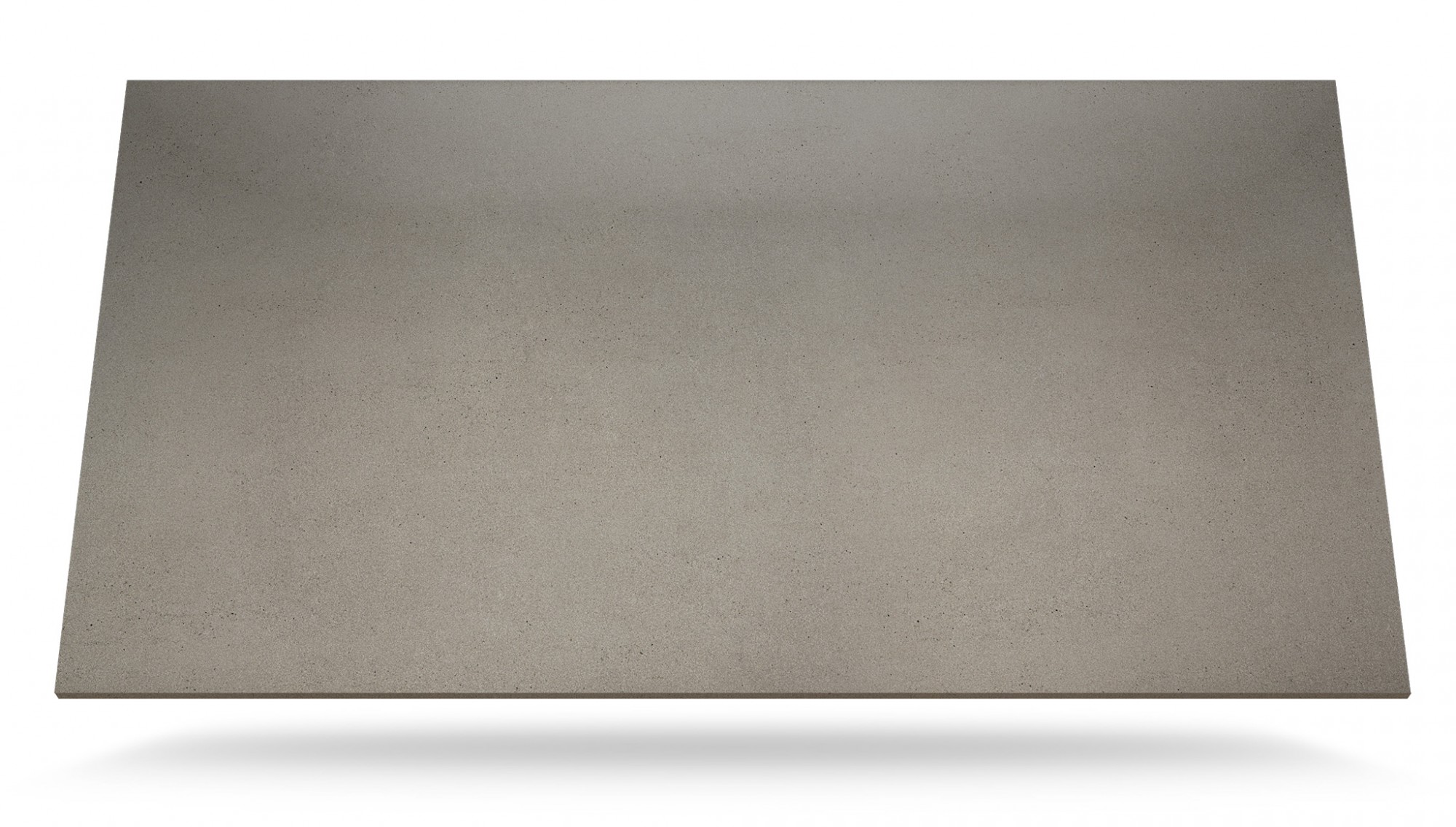

Pattern & Color

Ultra compact surface countertops come in a range of colors and tones. The palette tends to be on the earthy and neutral side, making the countertop integrate nicely into your current room design.

Note that while this surfacing offers full body coloring, the pattern and texture does not go through the full body of the material. So, in the rare event of damage, the pattern will be noticeably disrupted.

Maintenance Tips

These countertops offer a lot of great qualities that make them very easy to maintain. But, you should still be aware of how to maximize the life of your new countertops.

Daily cleaning is simple. Due to the virtually zero porosity, it’s highly resistant to staining from day-to-day use and chemical products. For the most part, the best option for cleaning is just a neutral soap and water with a sponge or scouring pad (avoid metal).

There are some specific cleaning products with alkaline, solvent or acidic agents that may be used in certain cases—according to Cosentino, manufacturer of Dekton ultra compact surfacing.

But, generally, care for these countertops the same way you would any other material: With basic care and hygiene in mind. Clean up any spills quickly and always rinse and dry well. Be mindful of corners, edges and bevels, as those more exposed areas are more vulnerable to knocks.

Before You Buy: Need to Knows About Ultra Compact Surfacing

These countertops are a great option, but there are some practical considerations you should know.

Because of ultra compact surfacing’s distinctive properties, it requires specific fabrication techniques and equipment. Not all fabricators have received this training or have the proper machinery. Therefore, not all fabricators offer this innovative product. Due to its relative newness in the market and other factors, it can be more expensive than other alternatives – but not by much. Just like any other countertop purchase, total price depends on a number of factors, including:

- How many cut-outs you need to fit things like sinks and faucets

- The size and shape of your countertop perimeter and island

- The uniqueness of the color, pattern and texture

- Slab thickness

- Other installation fees, like tear-out costs

Ask your countertop supplier about their practical experience with this product category. Expertise with this material is important, otherwise you risk a botched result or an install that doesn’t live up to your expectations.

With this in mind, who makes ultra compact countertop surfaces and how can you get it?

Manufacturers

Dekton is considered the pioneer of ultra compact surface countertops and the leading manufacturer of the material. Dekton is a product of Cosentino, who also produces the Silestone quartz countertops we all know and love!

Strato by Dekton

Entzo by Dekton

Eastern Surfaces has been fabricating the Dekton product in the eastern Pennsylvania area for years now as an early adapter—and the surface is displayed at our showroom. We’d love to help you bring this beautiful and functional surface into your home (or outdoor space)!

Ready to try ultra compact surfacing? Browse our current inventory of Dekton or schedule time to visit our showroom to learn more.